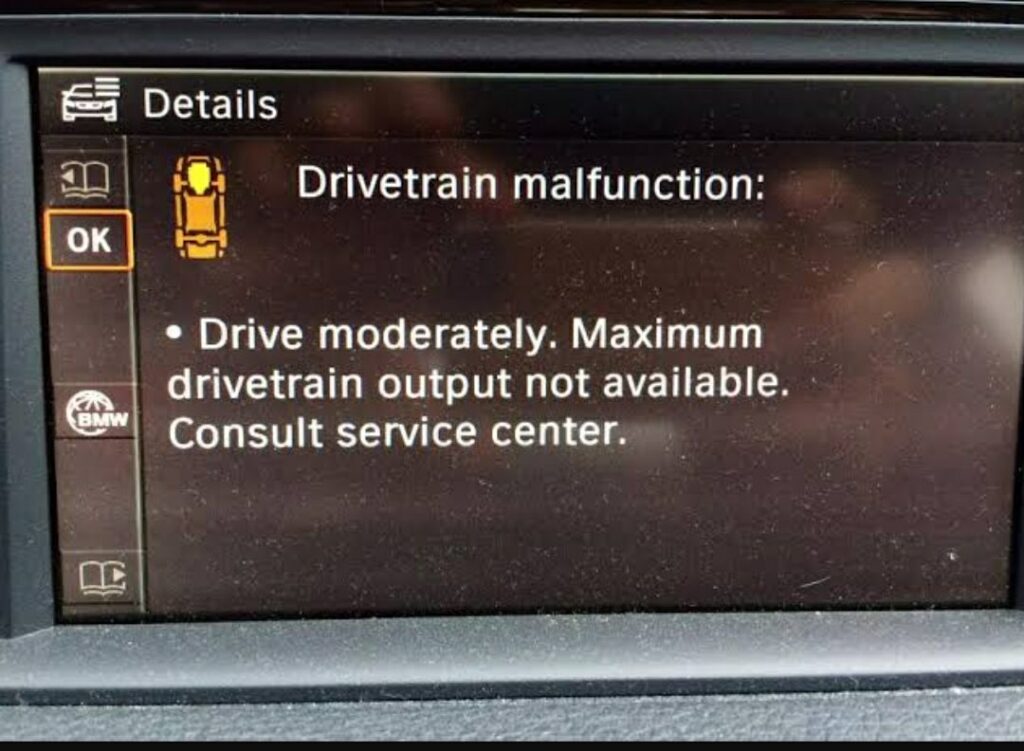

Drivetrain malfunction bmw warning indicator start illuminating on the iDrive screen of bmw. When there is any problem occurs at engine compartment or automatic transmission. Most of the time drive train malfunction indicator warning illuminate on iDrive screen when engine control module detect problem related to engine power. Most of the time this warning indicator start illuminating when engine does not deliver require amount of pickup while driving at high speed.

Causes of Drivetrain malfunction bmw:

- Low fuel pressure in the fuel supply system.

- Failure of any sensor.

- Damage wiring harness of any sensor.

- Faulty actuator.

- Failure of turbocharger supercharger.

- Block exhaust gas recirculation valve.

- Block diesel perticualte filter.

- Leak of air into combustion chamber through air intake area.

- Electrical problem at automatic transmission.

- Failure of automatic transmission control module.

Symptoms of Drivetrain malfunction bmw:

- Check engine light will start illuminate on cluster meter.

- Warning indication on the iDrive screen.

- Lack of power while driving at high speed on high way.

- Miss firing engine at idle position.

- Excessive vibration at engine compartment.

- Engine does not start when crank.

- Smoke from exhaust gas end.

- Engine cut of while driving from high speed to low speed.

How to trouble shoot:

When drive train malfunction indication illuminate on iDrive screen. You need to inspect your engine to find out the reason behind this malfunction. To find out the reason, hook up scan tool and check fault code store in control module.

Most of the time this fault code store in control module when engine does not deliver require amount of power while driving. This problem could be happed due to multiple reasons. As there are many sensor and actuator present at engine which is responsible to engine power.

If fault code is store in control module of about related to fuel pressure low. Than it means that there is some problem at fuel supply system. In this situation you need to check fuel supply system.

Condition #1:

Fuel supply system consist of many parts. Low pressure fuel pump fitted inside fuel tank, fuel pipe line, fuel filter, high pressure fuel pump, fuel rail pressure sensor and injectors.

You need to check each every parts of fuel supply system so that you can find out the faulty parts which is causing low fuel pressure in the system.

First check pressure of fuel from low pressure fuel pump. Pressure of fuel should match the required pressure according to the manufacturer. If it fuel pressure match the require pressure than it means low pressure fuel pump is working fine

Now check leak at fuel pipe line, if found any damage then repair or replace that fuel pipe line. Than check fuel filter, if fuel pressure before fuel filter is good but after fuel filter fuel pressure drop than you need to replace fuel filter.

If fuel pressure is good before high pressure fuel pump. Than check the pressure of fuel after high pressure fuel pump. If fuel pressure does not match the require fuel pressure than you need to check high pressure fuel pump. Repair or replace high pressure fuel pump so that problem of low fuel pressure can be solve.

A fuel pressure measuring sensor is located at the end of fuel rail which is known as fuel rail pressure sensor. Check the condition of fuel rail if there is any leak found at fuel rail than stop that leak. Because most of the time fuel leak from the joints of fuel injector pipe connection. If there is no leak and still fault code show low fuel pressure fault, than replace that fuel rail pressure sensor. Because a faulty fuel rail pressure sensor can also cause fault code of low pressure in the system.

Condition #2:

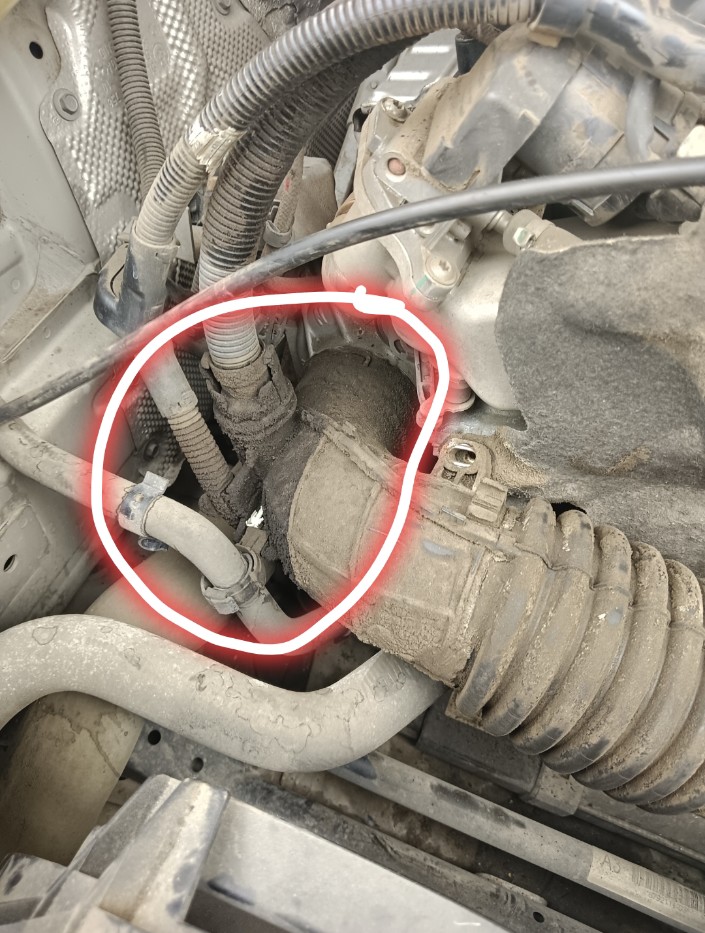

When engine control module store fault code related to air leak into combustion chamber. It means that there is some leak from where air enter into combustion chamber. You need to check visually at the pipe line of air intake. As there are many pipe you can see at engine which are connected to air intake pipe. Check if there is any leakage found at all those pipe than close that leak.

But if there is no leak at the outer pipe line or air than it means that the leak is now at the joints of intake manifold. In this situation you need to check the joint of intake manifold. You can find out this types of miner leakage with the help of smoke test. When found any leak at the intake manifold due to any reason. Remove intake manifold and check the rubber packing of the intake manifold. Most of the time that rubber packing get damage due to which engine air leak into combustion chamber. Replace that rubber packing and then refit the intake manifold. Now check if air leakage stop than take a test drive of vehicle and check if malfunction light still illuminate or not.

Condition #3:

In this situation you need to check sensor which play an important role in the engine performance. Like crank sensor, sometime this problem store in control module due to the failure of crank sensor. As crank sensor is use to monitor the rotational speed of engine and send this signal to engine control module. When crank sensor did not send signal to engine control module than also this kind of problem occurs. Check the condition of crank sensor if there is any damage on crank sensor than replace than replace faulty sensor.

If crank sensor is in good condition than check the flywheel which is connected with engine. As crank sensor sense the rotational speed of engine through fly. If fly wheel will have any damage than crank sensor will send faulty signal to engine control module. Check flywheel if there is any damage found than repair or replace it. So that crank sensor can sense the proper rotation of engine.

Condition #4:

If fault code store in control module of about block diesel perticualte filter. It means that diesel perticualte filter is block due to which exhaust gas is passing through than also engine will not provide power while driving at high speed. You need to solve the problem of block diesel perticualte filter. Which could be happened due to failure of sensor or block diesel perticualte filter due to diesel shoot. Check if sensor is faulty than replace that sensor and if diesel perticualte filter is block. Than clean diesel perticualte filter with the help of scan tool. By performing cleaning diesel perticualte filter process. So that engine exhaust gas can pass exhaust air through diesel perticualte filter and engine can deliver require amount of power while driving at high speed.

Condition #5:

Check fault code store in automatic transmission control module. As transmission control module is also a participant in the engine power or pickup. If there will be any problem occur in the automatic transmission control module than also this warning light will illuminate on iDrive display. Check problem at automatic transmission control module or inside transmission mechanical parts. If found any damage parts or any faulty sensor of automatic transmission than replace that.

Solution of Drive train malfunction bmw:

Repair or replace faulty parts of fuel supply system.

Replace faulty sensor.

Repair damage wiring harness of any sensor.

Replace faulty actuator.

Replace faulty turbocharger supercharger.

Clean exhaust gas recirculation valve.

Clear out block diesel perticualte filter.

Close the leak of air into combustion chamber through air intake area.

Solve electrical problem at automatic transmission.

Replace faulty automatic transmission control module.

Also read:

244800 particulate filter system limited remaining.