Fault code 25d400 exhaust back pressure sensor before turbocharger area, upper physical limit exceeded indicate problem towards exhaust back pressure sensor. Exhaust back pressure sensor is used to monitor pressure in the exhaust system. Send this information to engine control module which is used to control performance of the engine.

Engine control module deicide to inject fuel in combustion chamber according to the signal from exhaust back pressure sensor. When exhaust gas pressure fail. It stop sending signal to engine control module. In result which engine control module does not able to decide that how much amount of fuel should be inject into combustion engine. Due to which engine performance become worst. Also the chance of clogging diesel particulate filter get increase.

Causes of 25d400 exhaust back pressure sensor:

Faulty exhaust gas back pressure sensor.

Damage wiring harness of exhaust back pressure sensor.

Blown fuse.

Clogged diesel particulate filter.

Carbon deposition at turbocharger.

Clogged exhaust gas cooler actuator.

Smptoms 25d400 exhaust back pressure sensor:

Engine performance issue while driving.

Excessive black smoke from exhaust.

Check engine light will illuminate on cluster meter.

Fault code will store in control module.

How to trouble shoot:

When engine performance become worst or feel issue while driving. Than you need to do inspection of vehicle with the best experienced workshop?

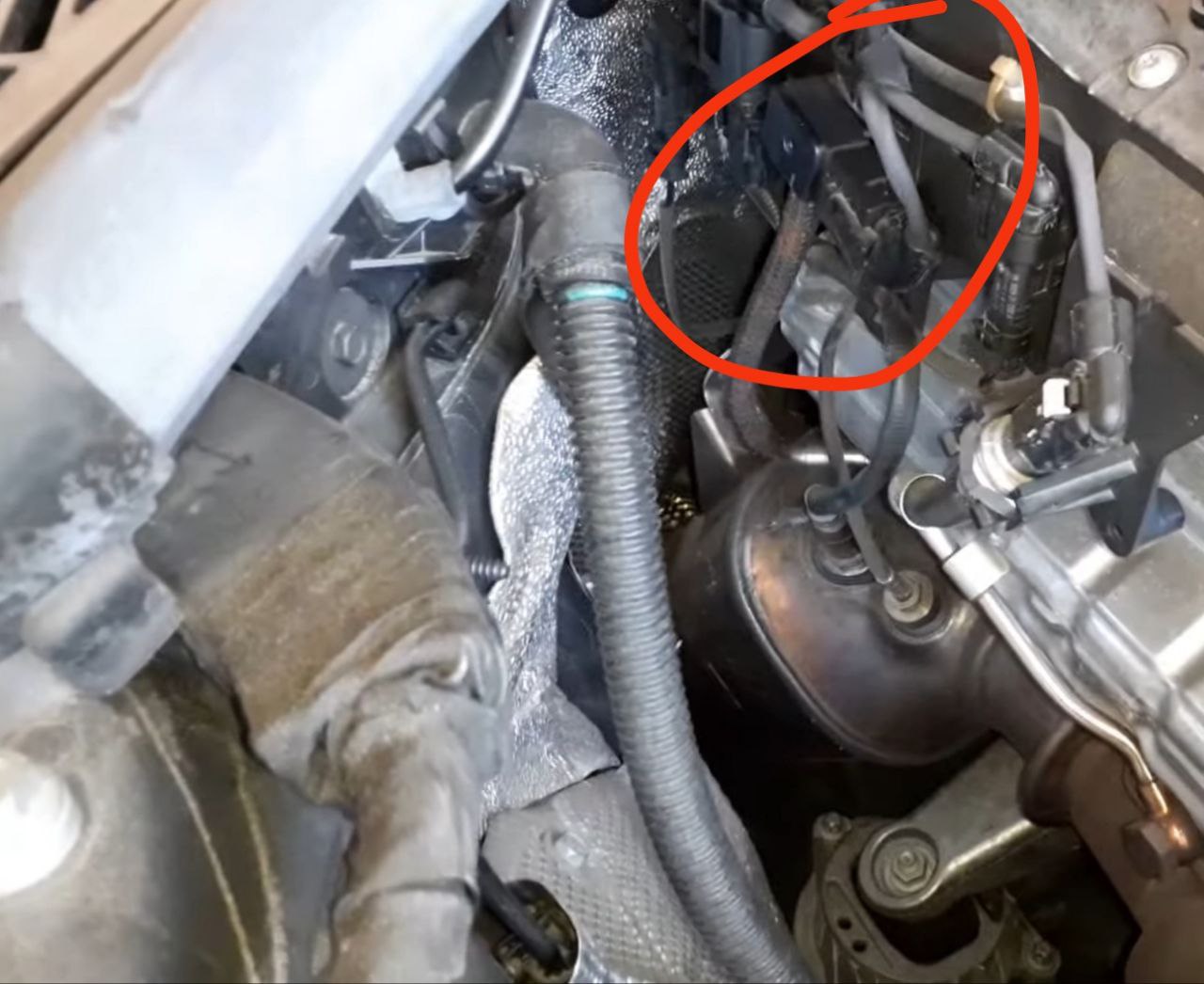

Hook up the scan tool to find out fault code store in control module. When found fault code store in control module, you need to check the reading of exhaust back pressure sensor with the help of scan tool. Reading of the sensor should be fluctuating every time when accelerator pedal is pressed.

Start engine, pressed accelerator pedal and check reading of sensor in scan tool. If reading is fluctuating when accelerator pedal is pressed that. Than it means that sensor is not completely fail. It can be reuse after cleaning with cleaning agent or some alcohols. Remove exhaust back pressure sensor from its location, dip it in the solution of cleaning agent. Wait for some time and then after cleaning it refit it at its location. Now start engine and check if fault code is still store in engine control module. If fault code is still present than erase the fault code and now check if sensor reading is fluctuating or not.

when sensor reading is fluctuating, take a test drive and check the performance of the engine. If issue of engine performance is now solve than it’s good. Cleaning sensor idea does work, but replacing it with new sensor is every time a good idea. But if it does not solve the problem of engine performance issue. Than you will need to change this sensor to solve this problem.

If after replacing exhaust back pressure sensor fault code is not erasable. Than check if diesel particulate filter is bock or not. Because when diesel particulate filter will be block than also this fault code will be store in control module. As when diesel particulate filter will be block than exhaust gas will pass to outside. Exhaust gas have minor particles which get store on the exhaust back pressure sensor. Then also this this fault code could be store in control module.

Also check if there are some more fault codes store in control module. Like problem at charge pressure actuator, charge pressure sensor etc. than it could be possible that there is no problem at this sensor. Because when there will be the problem of charge pressure sensor actuator opening and closing. Than turbocharger will not open properly, due to which engine will not get enough air to make a proper air fuel mixture. In result which fuel does not burn in combustion engine. Due which there is a fault of exhaust back pressure sensor.

In this situation there is one more thing that could be the reason behind this fault code. That is faulty charge air pressure sensor, which is located at the intake manifold. This sensor is use to monitor the pressure of air entering into combustion chamber. Failure of this sensor can lead to irregular message to engine control module. In result which engine control module will either inject more fuel or low amount of fuel in to combustion chamber? Due to which air fuel mixture get disturb and does not burn in combustion chamber. Fault code of exhaust back pressure sensor can be also store in control module due to this reason.

How risky it is to drive with:

Driving with this fault code is not a good idea, as when this fault code will store in control module. Engine performance will not be good as per expectation. In this situation it could be possible that exhaust amount of black smoke will be coming out while driving. So driving with this fault code store in control module would not be good.

Solution:

Replace faulty exhaust gas back pressure sensor.

Repair damage wiring harness of exhaust back pressure sensor.

Replace blown fuse.

Clean clogged diesel particulate filter.

Clean carbon deposition at turbocharger.

Remove and clean clogged exhaust gas cooler actuator.

Special note:

When found this fault code store in control module. Always confirm all the symptoms of this fault code with vehicle. When fault code is confirm than only replace this sensor. Otherwise go to deep diagnosing process to find out the reason behind this fault code store in control module. Like check if there is any other fault code is store in control module as explain in above section. Because this fault code could be store in control module due to some other reason also. So before replacing exhaust back pressure sensor signal.